The fountain pen hobby requires more than just a well-made pen to be enjoyed. To have an excellent writing experience, writers also need good paper and, equally as important, well-made ink. You may have wondered how fountain pen ink is made in the first place. What is it that makes it especially suitable for fountain pens, and what are its properties that allow it to write well? Here, we’ll talk about the different components that make up fountain pen ink to give you an idea of how it’s created for use.

What is fountain pen ink?

Fountain pen ink is essentially liquid that is comprised of water, dyes, and other additives. Knowing the exact ingredients of any writing ink can be difficult as they are closely protected by ink manufacturers, but you can expect your fountain pen ink to contain the following: dyes, surfactants, humectants, and fungicide. Some inks may also contain perfume to mask other strong scents as well as other additives.

Dye

There are many types of dye that are used in fountain pen inks. The type of dye that is used depends on the desired color and properties of the ink. To make fountain pen ink, it is a requirement that the dye is soluble in water without falling out of the solution, and it must also be compatible with fountain pen materials such as plastic, precious metals, and resin.

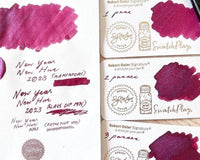

Dyes are made up of different natural and synthetic components depending on the color being produced. Red inks are known to contain eosin, an acidic compound. Blue inks contain triarylmethane dyes while yellow inks contain tartrazine, a synthetic food dye. Given this combination of primary colors, manufacturers should be able to make any ink hue.

Other dyes found in bulletproof inks are similar to the ones used to dye cotton, which are cellulose reactive and bind to paper and cloth. Aniline dyes are also used due to their vibrant and fade-resistant characteristics.

Surfactants

Without surfactants, your fountain pen ink would be mere water and dye. Surfactants lower the surface tension in water, strengthening the capillary action and improving inkn flow. In other words, it allows the ink to spread more easily instead of pulling into itself. Manufacturers carefully ensure that the ratio of surfactant to fountain pen ink is measured properly. This gives it good flow while ensuring it does not spread out too much, which may cause feathering on paper.

Humectants

Humectants are responsible for how quickly inks dry, both on your nib and on paper. Fountain pen ink manufacturers use a humectant called glycerin to change how fast inks can dry. The more humectant is added to ink, the slower it will dry when placed on paper. This also means that your nib will stay wet for longer while uncapped. More lubricated inks tend to have more humectants in them, giving them a smoother feel across paper but usually at the expense of faster dry times.

Fungicide

Fungicides are what keep your inks free of bacteria, fungi, and mold. This is an essential component in fountain pen ink that prevents any unwanted growth that can damage your fountain pens. The wetness of ink bottles and the presence of glycerin make fountain pen inks an ideal environment for mold growth, so fungicide is crucial.

Other fountain pen ink components

There are many other additives that can be added to fountain pen inks to give them special properties. Some of the most common are shimmering and sheening particles that give inks beautiful shining and reflective characteristics.

There are also fountain pen inks that contain nano-pigments, which are pigment particles that are extremely small and suspended in the fountain pen ink. This gives the ink waterproof and feather-resistant properties. The best examples of this type of ink are Sailor Nano-Pigment or Platinum Carbon Black.

The Bottom Line

Knowing what your fountain pen ink is made of can help you determine what to look for when purchasing ink. It can help you understand why some inks behave differently compared to others, which can lead to better-informed choices when shopping. For instance, some of the best fast-drying inks will likely have a lower level of humectants. You can also use this knowledge when experimenting with your inks at home; simply add a smidge of dish soap to your drier inks and watch them become better lubricated than if you added water.

As always, happy inking and happy writing!

Written by EndlessPens Blogger Ramona Kabigting

1 comment

Sudip Basak

Madam,

Thanks for your article. I felt a problem. I am trying to make homemade fountain pen ink using lamp black. But lamp black is not diluting in water. It gets precipited. Would you please tell me how I can dilute the lamp black or is there any other type of dye to make homemade fountain pen ink?

Sudip Basak

From West Bengal, India